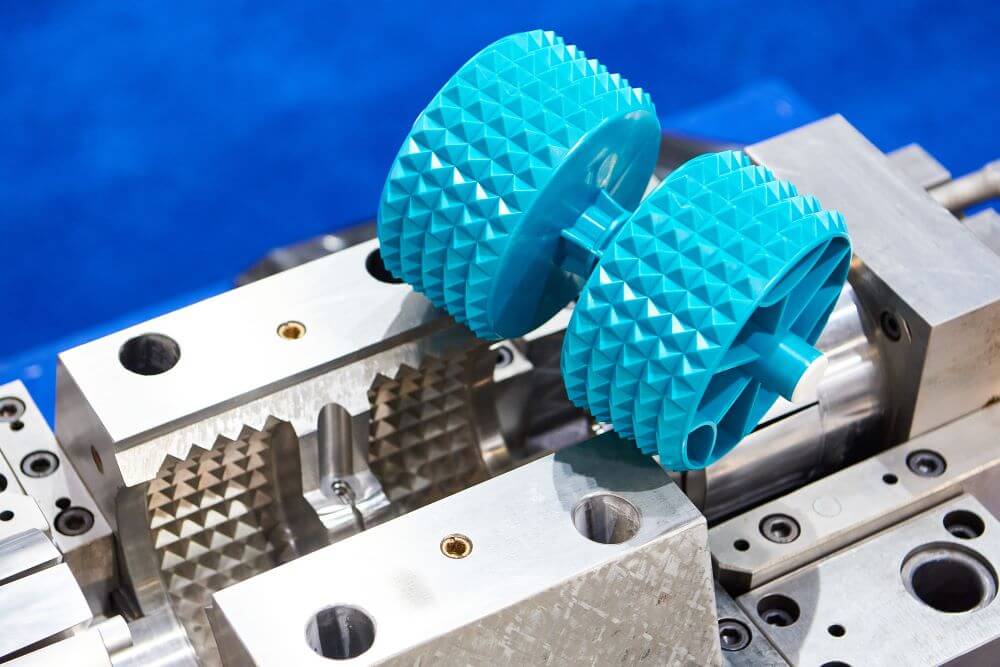

ORM USA specializes in thermoplastic injection molding, producing custom plastic parts for various industries such as aerospace, medical, and telecommunications. Our capabilities include:

Injection Molding Machines: Equipped with machines ranging from 50 to 400 tons of clamp force, accommodating shot capacities from 1.5 oz to 63 oz.

Material Expertise: Proficient in molding a variety of materials, including ABS, Nylon, Polycarbonate, and more.

Value-Added Services: Offering insert molding, overmolding, ultrasonic welding, heat staking, pad printing, thread tapping, and assembly services.

Quality Assurance: Adhering to AS9100D and ISO 9001:2015 certifications, ensuring high-quality production standards.

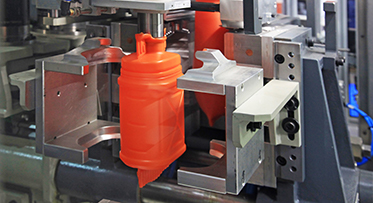

Roto molding, or rotational molding, is a manufacturing process used to create hollow plastic products. It involves heating plastic resin inside a rotating mold, allowing it to evenly coat the mold’s interior. This method is ideal for producing durable, seamless, and complex-shaped items like tanks, containers, and playground equipment.

ORM USA provides various metal casting services to produce complex and high-precision metal components:

Die Casting: High-pressure injection of molten metals like aluminum, zinc, and magnesium into steel molds for precise and repeatable parts.

Investment Casting: Utilizing wax patterns and ceramic molds to produce intricate components with excellent surface finishes.

Sand Casting: Employing sand molds for versatile and cost-effective production of large and complex parts.

Permanent Mold Casting: Gravity-fed casting using reusable molds, suitable for medium to high-volume production runs.

ORM USA offers forging services to produce strong and durable metal parts:

Open Die Forging: Ideal for large components, this process involves deforming metal between multiple dies that do not enclose the workpiece entirely.

Closed Die Forging: Also known as impression die forging, it uses shaped dies to compress metal into the desired shape, suitable for high-volume production.

Roll Forging: A process where metal is passed through rolls with specific profiles to achieve the desired cross-section.

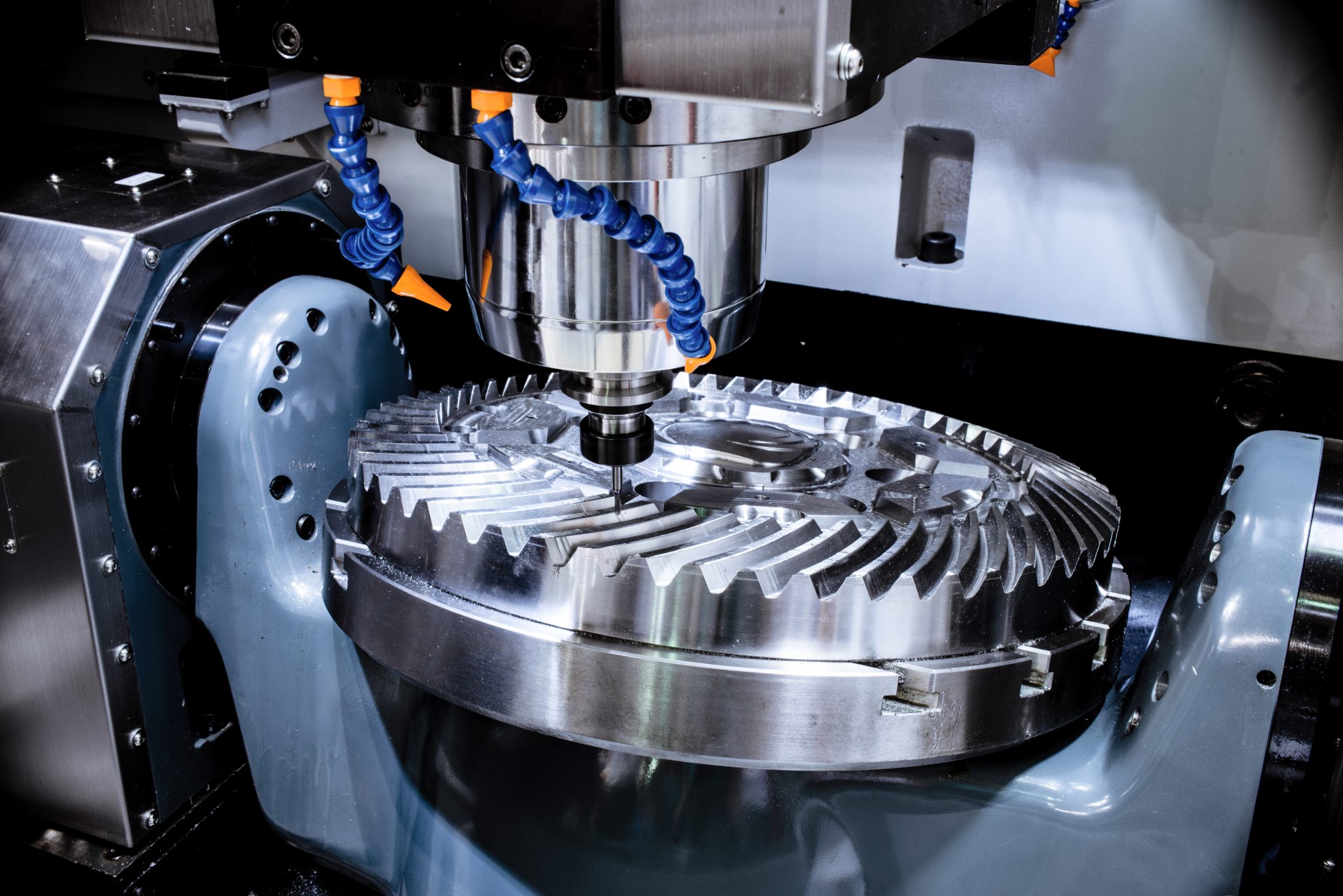

ORM USA’s machining services ensure precision and accuracy in manufacturing components:

CNC Machining: Utilizing computer-controlled machines for milling, turning, and drilling operations to produce complex parts with tight tolerances.

5-Axis Machining: Allows for the creation of intricate components by moving the workpiece along five different axes simultaneously.

Wire EDM: Employing electrical discharges to cut intricate shapes in hard metals with high precision.

ORM USA provides comprehensive fabrication services to assemble and construct metal structures and components:

Laser Cutting: Using high-powered lasers to cut materials into specific shapes with precision.

Welding: Joining metal parts together through various welding techniques to ensure structural integrity.

Bending and Forming: Shaping metal sheets into desired forms using press brakes and other machinery.

Tubular Fabrication: Specializing in the fabrication of tubular components for various applications.